1. Background Introduction

A certain railway bureau previously faced issues such as cumbersome tool checkout/return registration, frequent tool loss, lack of precise control over personnel entry and exit, and the urgent need to improve operational efficiency and safety management.

2. RFID Tool Binding Implementation Process

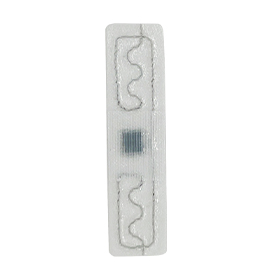

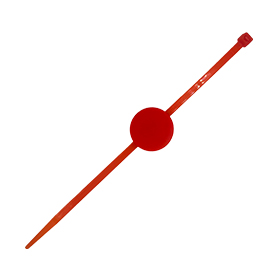

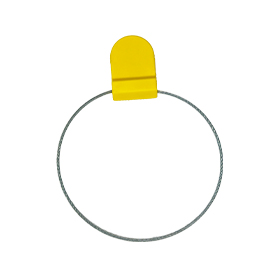

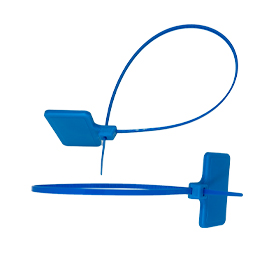

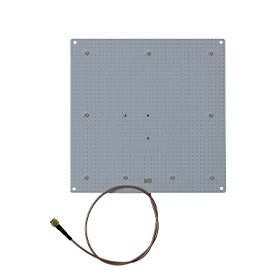

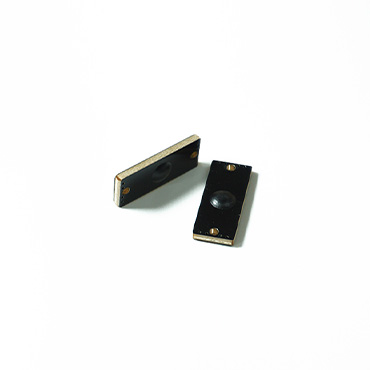

Tag Installation: GZY-2510 PCB anti-metal tag、GZY-1808 printable RFID Metal label is affixed to the surface of metal tools using 3M adhesive or screws.

Data Binding: The GZY-77 card issuer reads the tag's EPC code, and information such as tool model and serial number is entered into the system to establish a "tag ID-tool information" mapping.

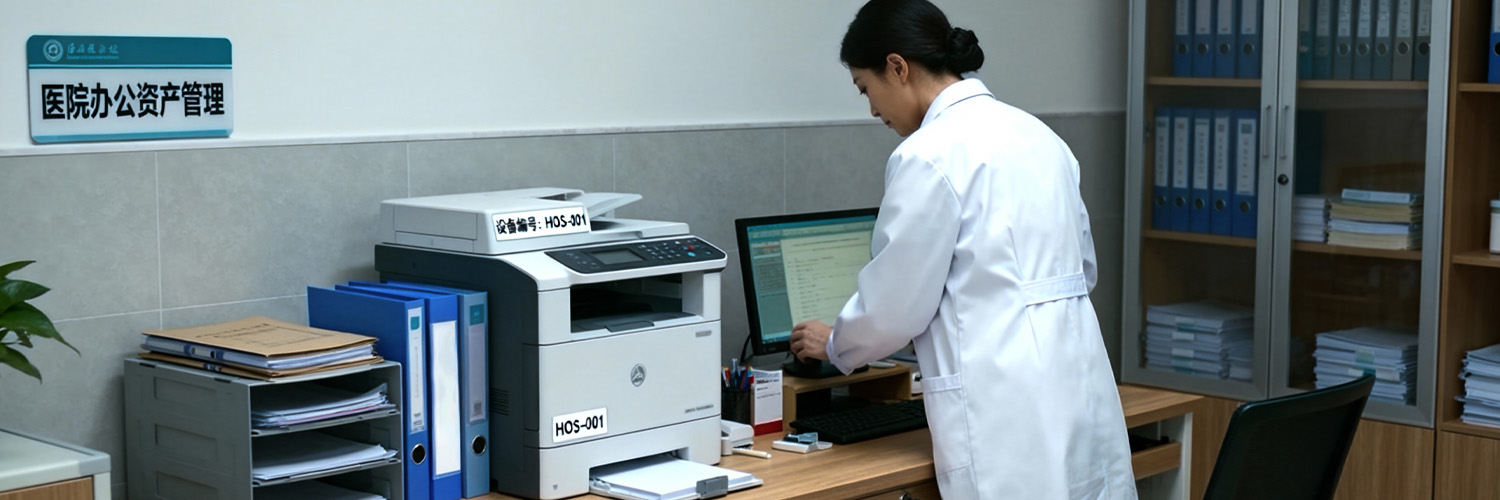

Permission Configuration: GZY-8654 PVC cards are issued to operators, with the system linking personnel identity to authorized tool ranges and setting checkout permissions.

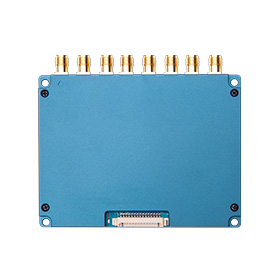

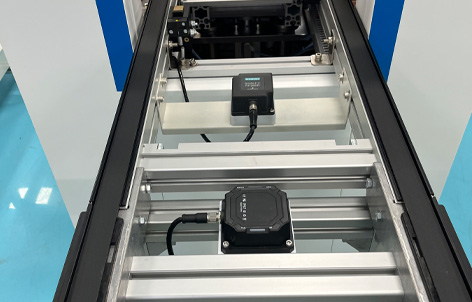

Verification Access: When personnel carrying tools pass through the GZY-C10 access gate reader , the reader simultaneously reads the personnel card and tool tag to verify permissions in real time: matching permissions grant access and record time; mismatched permissions trigger an alarm and block access.

3. Efficiency Improvement

Tool Management: Automated check-in/check-out registration to reduce manual operations

Personnel Access: Real-time permission verification to prevent unauthorized entry

Data Accuracy: Systematically tracks tool flow to minimize loss risks

Advantages:

Saves registration time

Enhances access control accuracy

Optimizes asset management efficiency