Project Background

A large automotive parts manufacturing plant in India faced challenges in tool management: traditional manual inventory-taking took up to 2 days per cycle, with an annual tool loss rate of 15%, and safety hazards due to expired usage. In 2024, they implemented a smart management system based on PCB anti-metal tags and GZY-E98 eight-port readers, achieving full lifecycle digital management of tools.

Hardware Configuration

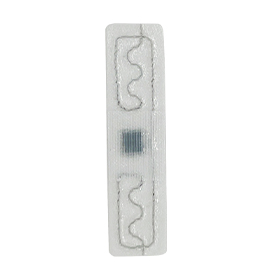

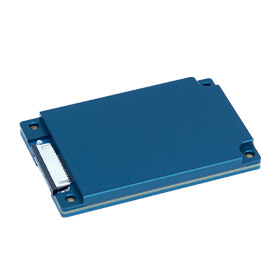

1.PCB Anti-Metal Tags: UHF frequency (860-960MHz), directly fixed to metal tools like wrenches and drills, resistant to high temperatures and corrosion, with a read range of up to 3 meters.

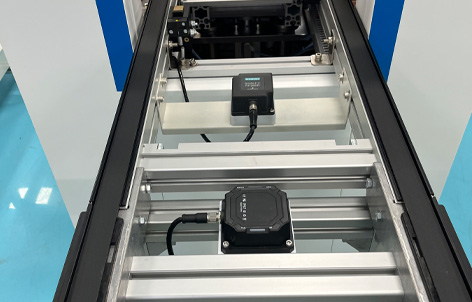

2.Smart Cabinet Integration:

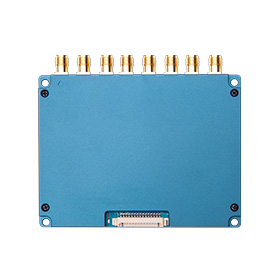

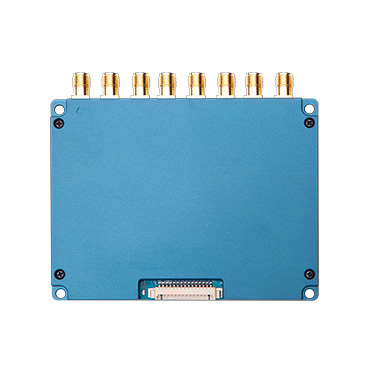

GZY-E98 Eight-Port Reader: Supports EPCglobal UHF Class 1 Gen 2 protocol, capable of batch reading (200+ tools/minute).

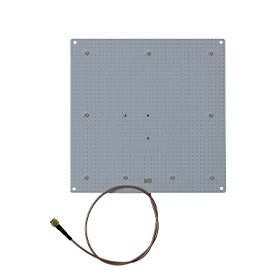

GZY-T2020 Antenna: Array layout ensures 99.9% recognition rate in metal environments, with strong anti-interference capabilities.

System Functions

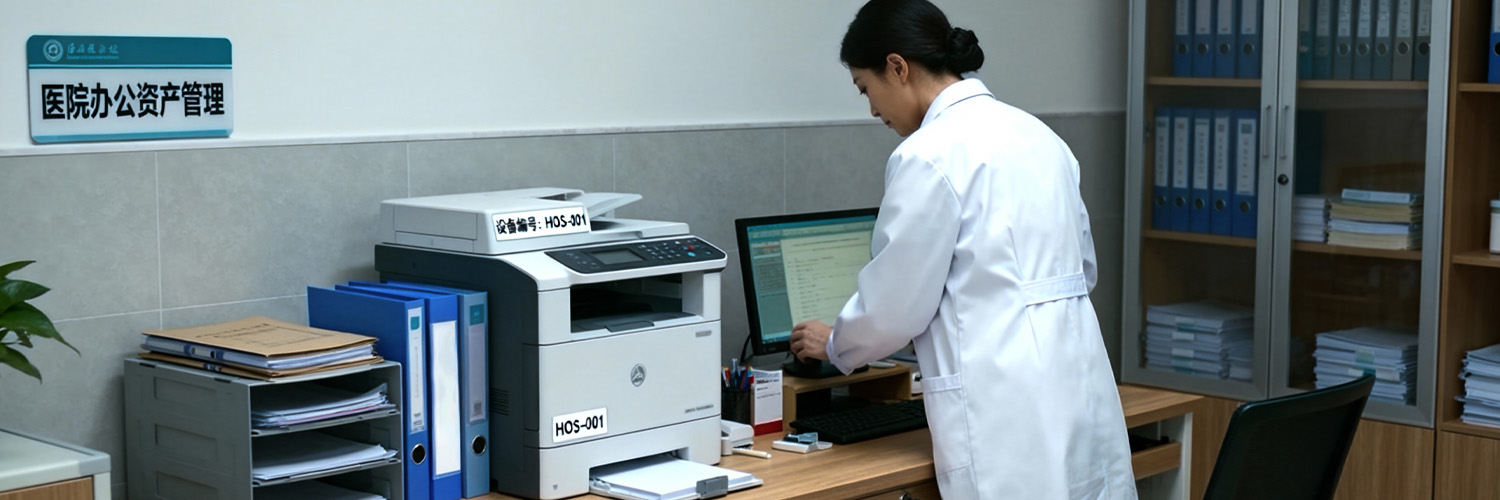

Automated In/Outbound: Tools are automatically identified when placed into or removed from the smart cabinet, recording time and operator, reducing processing time from 5 minutes per instance to 1 minute.

Real-Time Inventory: Inventory time for thousands of tools is reduced from days to hours, with 99.8% accuracy.

Permission Alerts: Access via work cards/fingerprint verification; immediate alerts for unauthorized actions (e.g., failure to return).