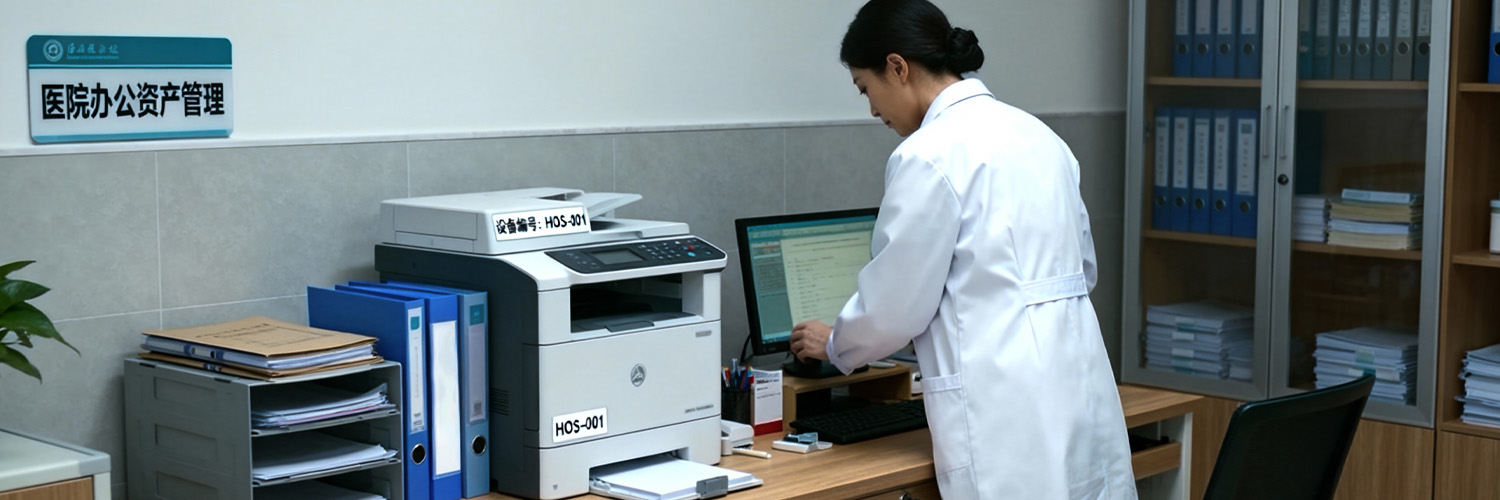

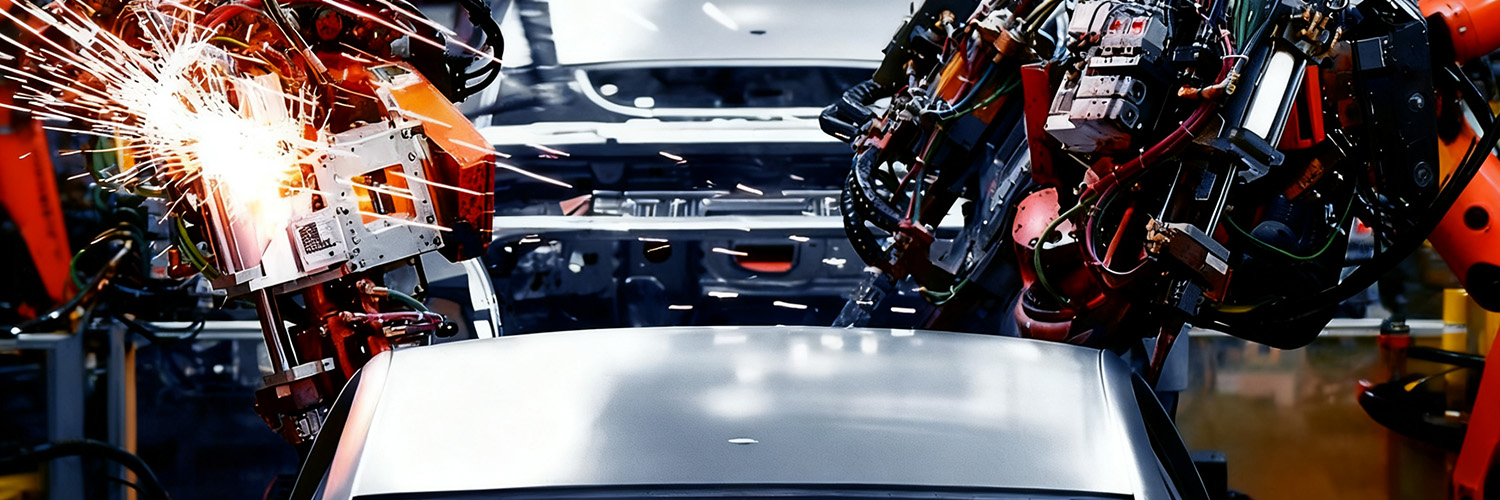

Application Overview

Achieving Goals

- Efficient Operations: Ultra-high frequency RFID quickly scans goods, reducing the time for single batch entry and exit from the warehouse and enhancing warehouse throughput

- Precise Data: Avoiding errors in manual and barcode entry, reducing data error rate to below 1%, ensuring accurate decision-making basis

- Real-time Monitoring: Real-time monitoring of goods' location, status and flow direction, promptly handling abnormalities, and enhancing management transparency

- Intelligent Inventory: Tracking the entire lifecycle of goods, dynamically managing inventory, reducing overstock and improving turnover rate

- Cost Reduction and Efficiency Enhancement: Reducing manual operations, lowering management costs and minimizing error losses

Solution

(1) System Composition

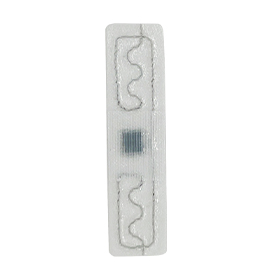

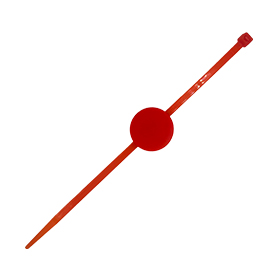

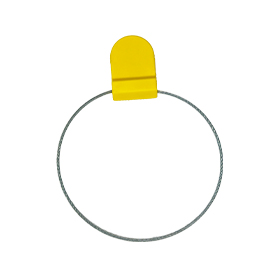

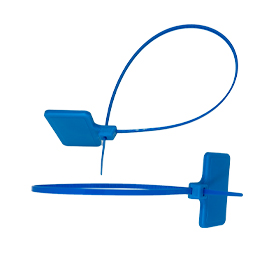

1. RFID Tags: Select tags such as self-adhesive, PCB anti-metal, etc. based on the characteristics of the goods, and install them on the surface of the cargo box or large metal tools, equipment, and devices.

2. RFID Readers

Channel-type Fixed Reader: Deploy fixed readers at the entrances and exits of the warehouse to automatically collect information about the goods. The reader connects to the server through the network and transmits data.

Handheld Reader: Provide handheld readers for warehouse operators for inventory checking and inquiries.

3. Warehouse Management System

(2) System Functions

Inbound and Outbound Management: Use the handheld reader to verify information during inbound, and automatically record the goods as they pass through the channel; for outbound, operate according to the order, and the system will alarm if the information does not match, ensuring accurate inbound and outbound of goods.

Inventory Counting: Use the handheld reader to scan the goods, and the system will automatically compare the inventory data and generate a difference report, facilitating inventory adjustment.

Monitoring and Warning: Real-time monitoring of the flow of goods, and automatic warning for situations such as stagnation, illegal entry and exit, and abnormal inventory.

Data Analysis: Analyze data such as the frequency of goods entry and exit and inventory turnover rate, and generate reports to assist in enterprise decision-making.

Permission Management: Set user permissions, back up data regularly, and ensure the safe and stable operation of the system.

(3) System Flow

Binding: Tag coding, printing, installation

Printing: Tag printing, display of information

Traceability: Fixed identification, statistics of entry and exit

Inventory Counting: Handheld inventory counting, clear inventory

Advantages

1. Efficient and Quick

Quickly identify multi-label goods, significantly enhance operational efficiency, and meet the requirements of high-speed logistics operations.

2. Precise and Reliable

Automatically collect data, avoid human errors, and ensure accurate and complete information.

3. Real-time Intelligence

Real-time monitoring and intelligent alerts, improving management response speed.

4. Flexible Expansion

Can be integrated with ERP and WMS systems, adapting to the business development needs of enterprises.

Related Devices

-

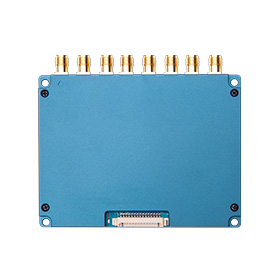

GZY-D8404Ports UHF RFID Reader4-Port RFID Split-Type Reader for Industrial-Grade Reliability, Lightning-Fast Identification, and Dual-Protocol CompatibilityRead More

-

GZY-T5099dbi RFID Circularly Polarized AntennaRFID ultra-high frequency 9dBi antenna, with strong anti-aging and weather resistance,

capable of stable operation in harsh environments.Read More -

GZY-202UHF RFID Handheld RederRFID handheld terminal reader, with high processing performance,

long tag reading distance and high group reading rate,

is widely used in logistics, asset management and other scenarios.Read More

Related Solution

No record