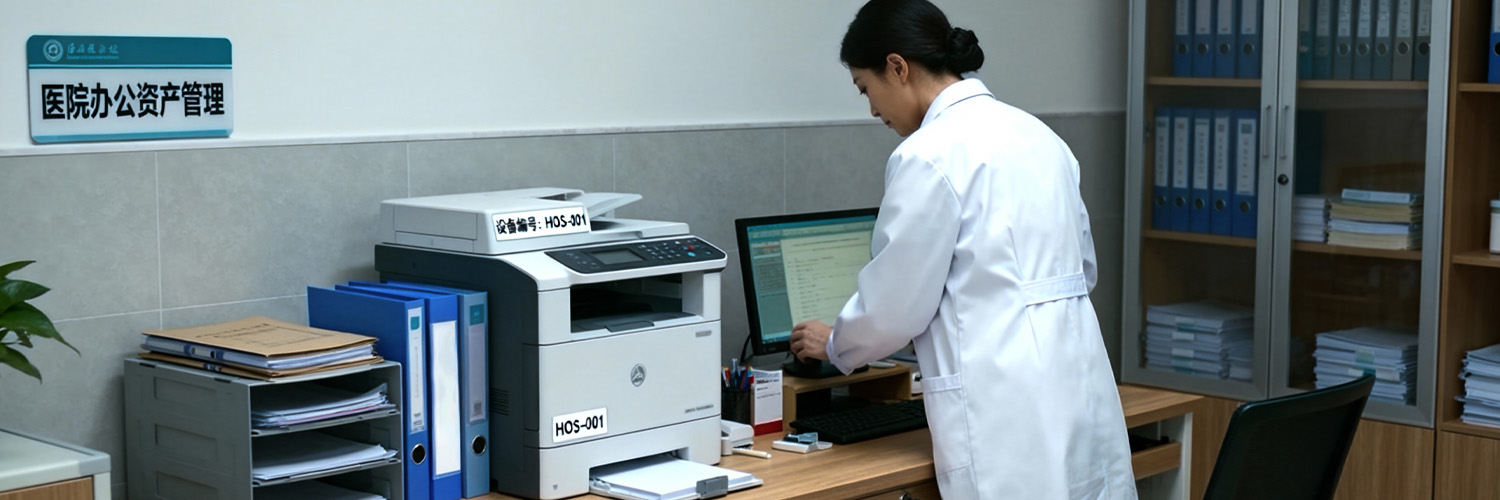

Application Overview

Achieving Goals

- Precise Tracking: Unique identification of linen, real-time tracking and positioning, reducing loss and misplacement

- Efficiency Improvement: Batch rapid identification, shortening time for inventory entry, sorting, etc.

- Process Optimization: Analyzing washing data, reasonably formulating plans, extending the lifespan of linen

- Quality Control: Recording quality inspection results, promptly handling unqualified linen

- Data Support: Generating reports, assisting in procurement, inventory, and other decision-making processes

Solution

(1) System Composition

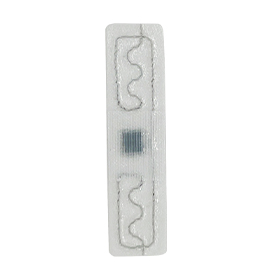

1. RFID Electronic Tags: Washing Labels, resistant to high temperatures, water, and abrasion, sewn onto the linen

2. RFID Readers:

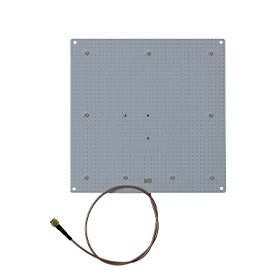

Fixed Readers: Installed at key positions to achieve contactless batch data collection

Portable Readers: Used by operators to complete the washing confirmation task with handheld devices

3. Linen Management System

(2) System Functions

Full Life Cycle Management: Covers all stages including storage, requisition, recycling, washing, quality inspection, and distribution, recording key information

Inventory Management: Real-time monitoring, setting alerts, and quick inventory checking

Data Analysis: Analyzing washing and loss data to generate various reports

Exception Handling: Alerting exceptions, tracing the full life cycle records of the linen

(3) System Flow

Registration: Register details in the linen management system and generate an electronic tag ID; use a desktop reader to write the washing sign code on the linen lable and sew it in linen to complete the registration

Storage: Linen enters the workshop through the entrance of the washing factory, the fixed reader at the entrance reads the tag and transmits data to the backend to update the status; placed according to rules in the washing area to complete storage

Outbound: Linen exits the workshop through the exit of the washing factory, the fixed reader at the exit reads the tag and transmits data to the backend to update the information; after packaging, it is completed as outbound.

Process Record: The backend system generates instructions according to business requirements, issues the washing confirmation work order; after the linen is washed, the operator uses the handheld reader to read the tag, transmits the data to the backend to update the washing information, and completes the washing task

Advantages

1. High Efficiency and Accuracy

Significantly enhance work efficiency while avoiding human errors and ensuring data accuracy

2. Cost Reduction

Automated management reduces labor costs and further lowers operational expenses

3. Full Traceability

Track and manage the entire lifecycle of linen

4. Data-Driven Decision Making

The system collects a large amount of data, providing managers with scientific analysis and decision-making basis

5. High Reliability

RFID electronic tags and reading/writing devices have good environmental adaptability

Related Devices

-

GZY-202UHF RFID Handheld RederRFID handheld terminal reader, with high processing performance,

long tag reading distance and high group reading rate,

is widely used in logistics, asset management and other scenarios.Read More -

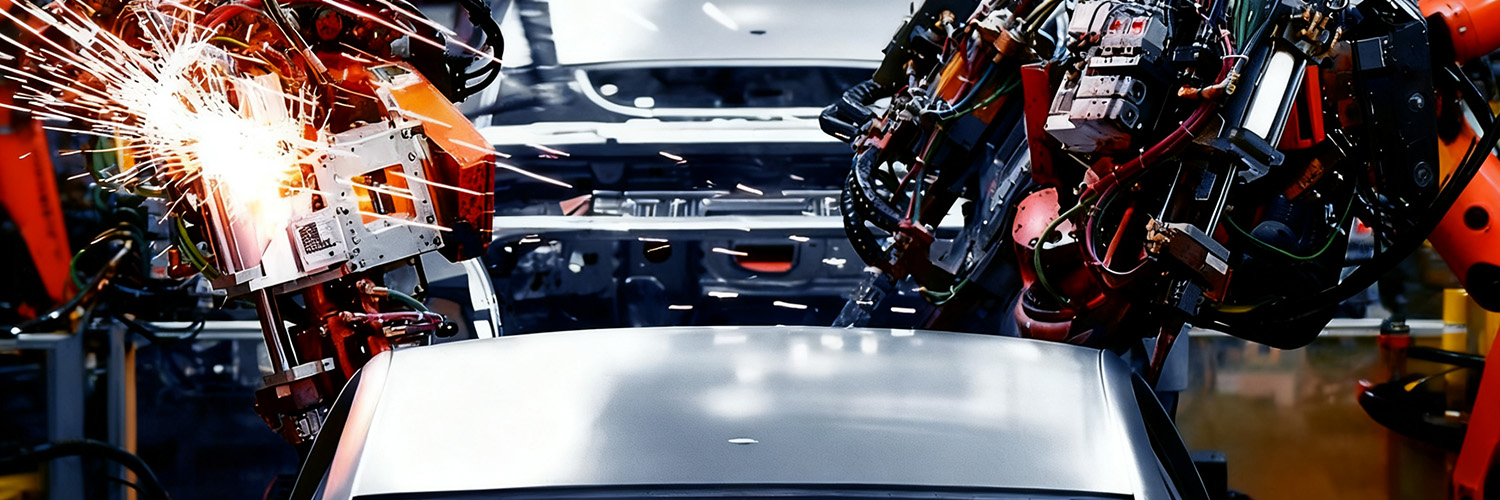

GZY-608UHF RFID Reader for Car Parking 6MUltra-high frequency integrated reader series, industrial RFID high-speed reader, IP65 protection with a 10-meter long-range, multi-mode intelligent control for vehicle logistics.Read More

-

GZY-77USB RFID Desktop Reader/WriterRFID Desktop Reader-Writer Series RFID

Card Issuance Device, Intelligent, Efficient, Flexible CommunicationRead More

Related Solution

No record