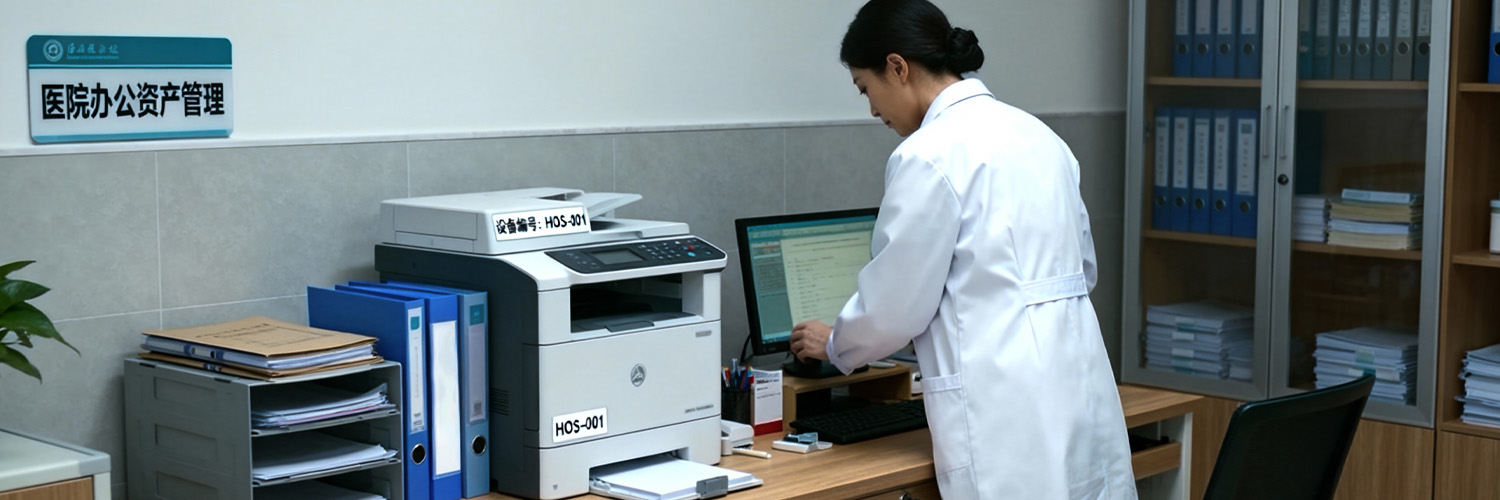

Application Overview

Achieving Goals

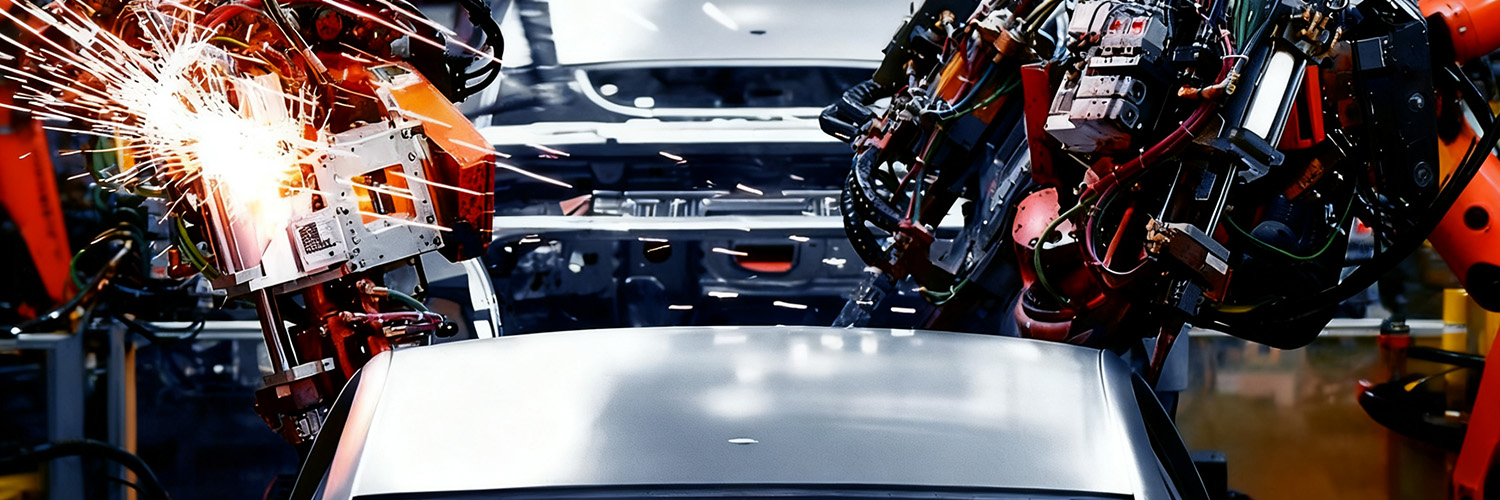

- Transparent Production: Real-time access to materials, progress, and equipment information, enabling production visualization and facilitating scientific decision-making

- Efficiency Improvement and Cost Reduction: Rapidly identify and collect data, shortening production cycles; Accurately manage inventory and optimize structure

- Quality Traceability: Recording key information throughout the product lifecycle, enabling rapid identification of quality issues

- Equipment Maintenance: Monitoring equipment status, implementing preventive maintenance, and enhancing utilization rate

Solution

(1) System Composition

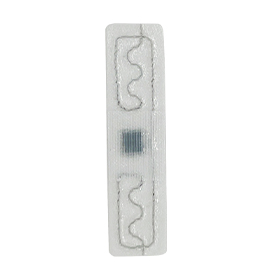

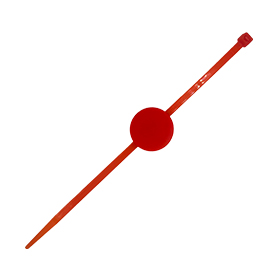

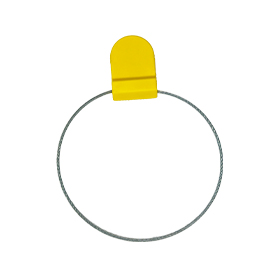

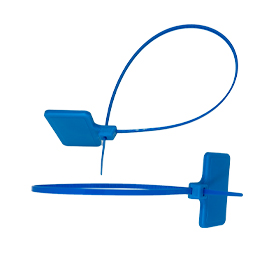

1. RFID Electronic Tags: PVC tray labels attached to the trays, fixed on the trays for material management; self-adhesive labels fixed inside or on the surface of the products, used for process confirmation

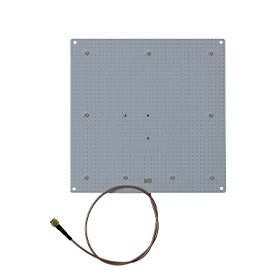

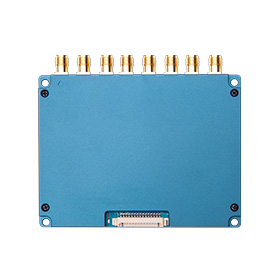

2. RFID Reader-Writer: Split-type reader-writer, installed at key positions of forklifts and production lines to ensure comprehensive and accurate identification of electronic tags

3. Production Line Management System

(2) System Functions

Production Monitoring: Track materials and work-in-progress, display progress, detect and handle abnormalities

Material Management: Automated inbound and outbound operations and inventory checks, generate inventory reports

Equipment Management: Collect equipment data, predict failures, and formulate maintenance plans

Quality Traceability: Bind product key information, quickly locate quality issues

Data Analysis: Generate various reports to provide basis for decision-making

(3) System Flow

Registration: Register product and tray details in the production management system, generate corresponding electronic tag IDs; use desktop reader-writer to write codes for both tags, fix the tray labels on the trays to complete registration; after placing the materials on the trays, bind the materials to the trays through the reader-writer, embed / stick the product labels onto the products to complete product registration

Inbound: Load the tray with materials into the production workshop, the fixed-type reader-writer at the entrance reads the tray labels, and the data is transmitted to the backend to update the material status; place according to rules to complete the inbound

Outbound: Move the raw materials and the tray to the exit, the fixed-type reader-writer at the exit reads the labels, and the data is transmitted to the backend to update the raw material information; the loaded tray leaves the workshop through the exit, completing the outbound

Process Recording: The backend system issues process confirmation forms to the RFID application according to business requirements; after the product completes the key process, the production line reader-writer reads its label, the data is transmitted to the backend to update the production information, completing the key process confirmation; after all processes are confirmed, update the product production information to achieve production process traceability

Advantages

1. Efficient and Precise

Automatically collects data, enhancing efficiency and accuracy

2. Strong Adaptability

Labels are resistant to harsh environments, reducing maintenance costs

3. Intelligent Management

Automated monitoring, enabling intelligent applications

Related Devices

-

GZY-202UHF RFID Handheld RederRFID handheld terminal reader, with high processing performance,

long tag reading distance and high group reading rate,

is widely used in logistics, asset management and other scenarios.Read More -

GZY-605Industrial - Grade RFID Integrated ReaderThe ultra-high frequency integrated reader series is a high-performance, all-weather industrial-grade fixed 5dBi reader.Read More

-

GZY-77USB RFID Desktop Reader/WriterRFID Desktop Reader-Writer Series RFID

Card Issuance Device, Intelligent, Efficient, Flexible CommunicationRead More

Related Solution

No record