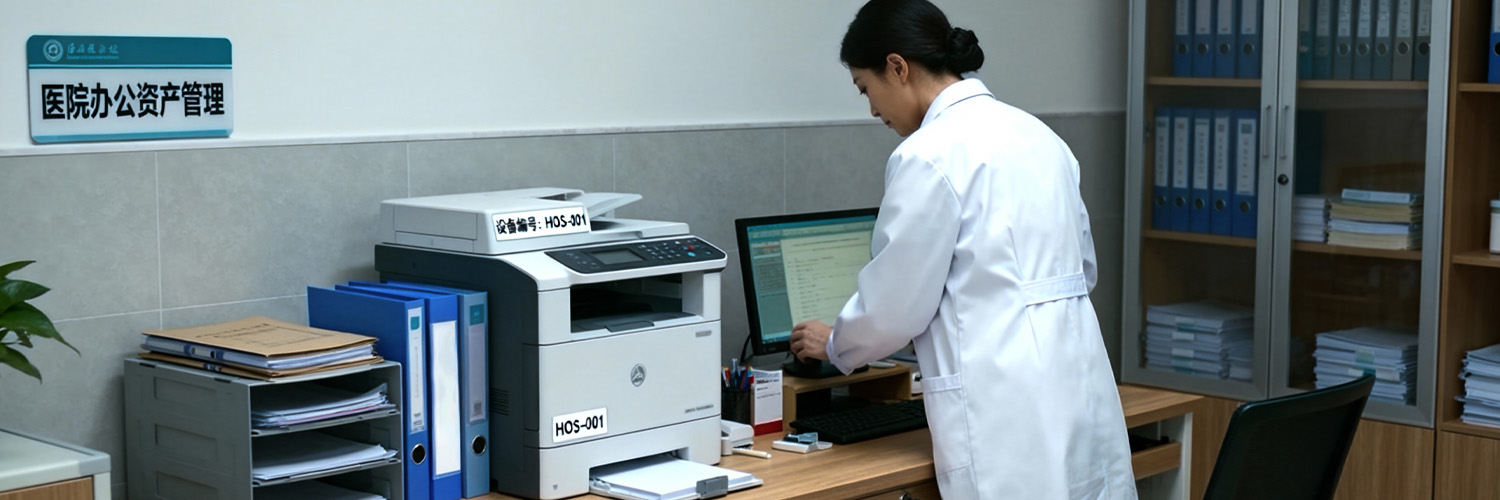

Application Overview

Achieving Goals

- Efficiency improvement: Automatic identification increases inspection efficiency by over 50%

- Accuracy: Data accuracy rate exceeds 99%, avoiding errors and omissions

- Monitoring: Real-time monitoring of inspection progress and equipment status, enhancing emergency response capabilities

- Decision-making: Analyzing data to assist management decisions, reducing failure rates and costs

Solution

(1) System Composition

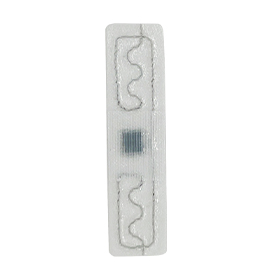

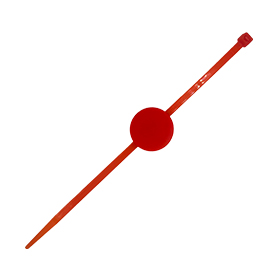

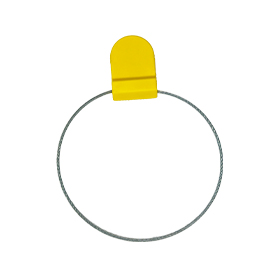

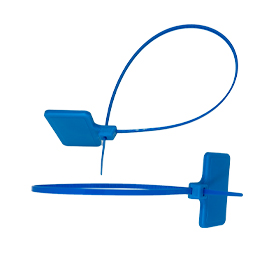

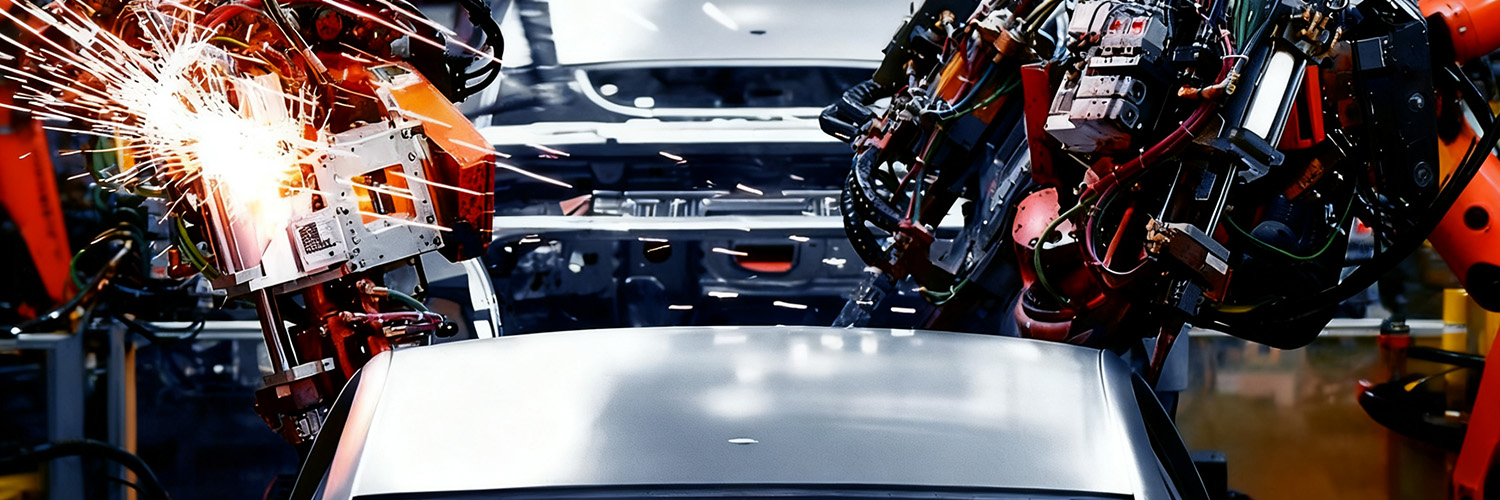

1. RFID Electronic Tags: Select tags with anti-metal and acid-base resistance properties according to the scenario, such as PCB tags and ABS tags. Install them at inspection points, facilities, and equipment surfaces.

2. RFID Reader-Writer: Handheld reader-writer, capable of quickly reading tag information, used for operators to perform inspection tasks. It has functions of storage, transmission, taking photos, and positioning.

3. Inspection Management System

(2) System Functions

Task Management: Flexibly formulate inspection plans and assign tasks, automatically remind tasks

Data Collection: Scan tags to automatically record information, support manual supplementation and photo upload

Monitoring and Alarm: Real-time monitoring, immediate alarm for abnormalities

Analysis Reports: Generate statistical reports to assist in decision-making

Archive Management: Record the entire lifecycle information of equipment

(3) System Flow

Registration: Register the inspection equipment / point details in the inspection management system, generate the corresponding electronic tag ID; use a desktop reader-writer to write codes on PCB or ABS tags; attach the tags to the corresponding equipment / points, completing the registration

Inspection: The back-end system generates inspection instructions according to business requirements, issues work orders to the front-end; upon reaching the corresponding equipment / point, use the handheld reader-writer to read the tags at close range; the data is transmitted to the back-end, generating an inspection list, completing the task

Advantages

1. Efficiency

Long-distance batch reading, automated collection and transmission

2. Accuracy

Avoids human errors, real-time monitoring of anomalies.

3. Reliability

Tags are adaptable to harsh environments, ensuring secure and stable data transmission.

4. Economy

Reduces operational costs, increases return on investment.

Related Devices

-

GZY-1221-2M Android RFID Handheld RederRFID handheld terminal reader, with high processing performance,

Multifunctional RFID warehouse inventory handheld device, integrating RFID and biometric identification,with excellent performance and stability.Read More -

GZY-77USB RFID Desktop Reader/WriterRFID Desktop Reader-Writer Series RFID

Card Issuance Device, Intelligent, Efficient, Flexible CommunicationRead More

Related Solution

No record