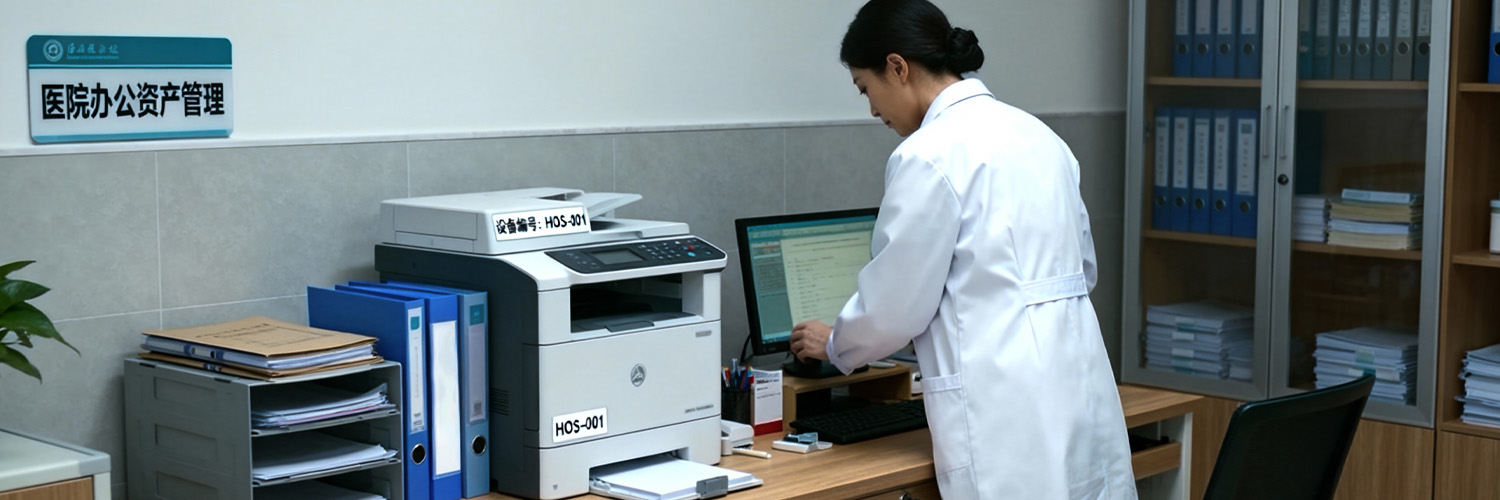

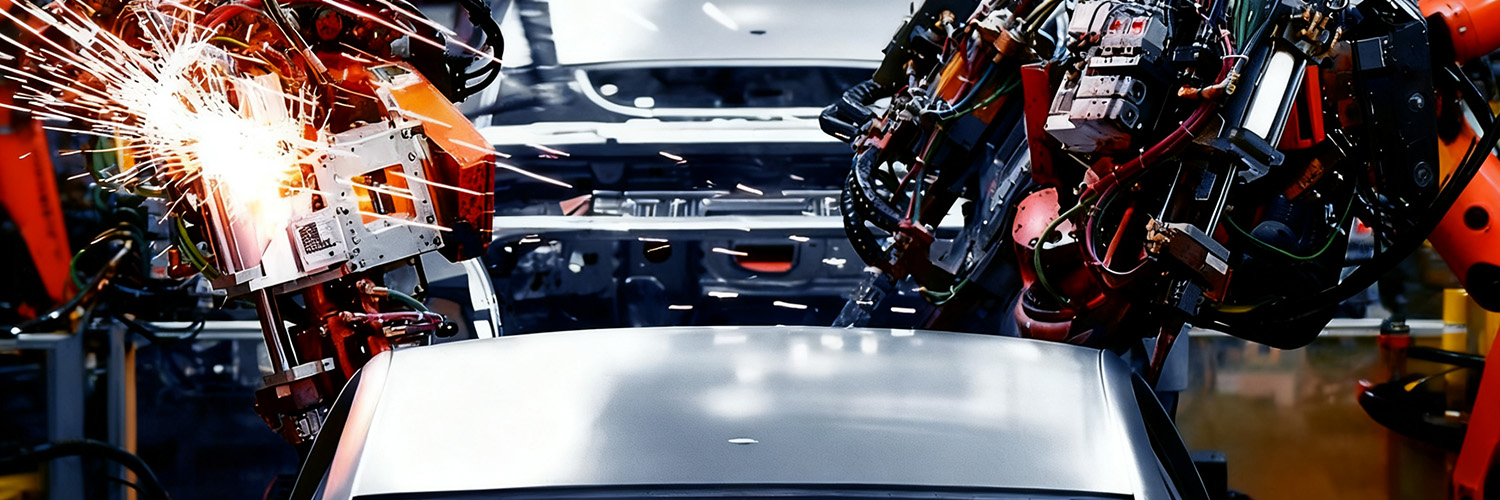

Project Background

A well-known electronics manufacturer faced mold mismatch and production line downtime issues. In 2025, it introduced an intelligent production line tracking system based on GZY series RFID equipment. Covering over 2,000 molds and components, the system optimized production processes via real-time material tracking, ultimately reducing the material error rate from 15% to 0.5% and cutting unplanned downtime by 40%.

RFID Hardware Configuration

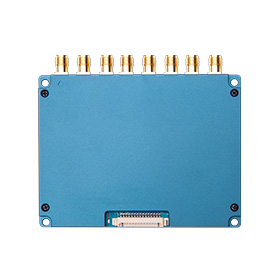

1. GZY-77 RFID Desktop Card Issuer: Writes EPC codes to magnetic tags and connects to the system for material information binding.

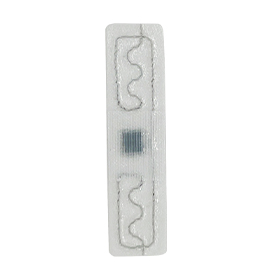

2. GZY-M6617 Anti-metal Tag: Withstands -40℃~85℃, magnetic design for direct attachment to metal material boxes, stable reading distance within 1m.

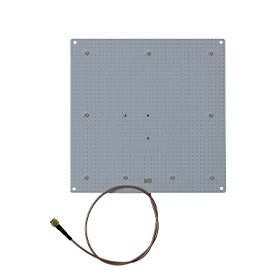

3. GZY-610 Industrial Reader: Deployed at key production line nodes, 1m stable reading distance, effectively distinguishes material status across processes.

System Functions

- Real-time Tracking: Records mold full lifecycle (usage count, maintenance history), integrates with MES for production scheduling optimization.

- Error Prevention: Automatically verifies material-order matching, reducing incorrect assembly rate by 90%.

- Efficiency Dashboard: Displays real-time production bottlenecks to support dynamic rhythm adjustment.